Robotic Arm:

Building my own DUM-E Robot!

Let’s face it. Every maker wants to become the next Tony Stark. And even though my Power Suit looked fun, it wasn’t really capable of protecting the world against the bad guys. Let’s work on something a bit more doable …

Robotic Arm:

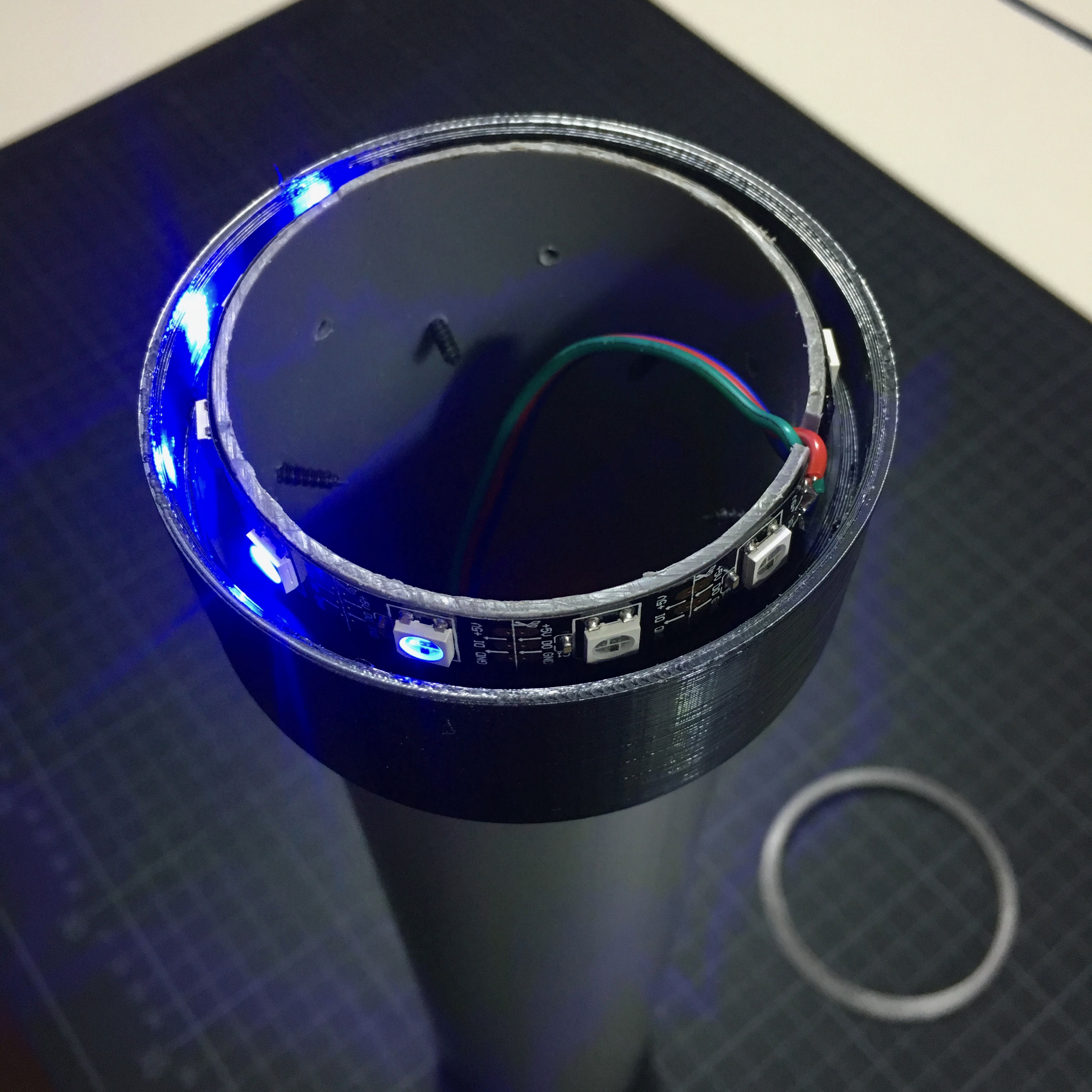

Illuminating the joint.

2 weeks ago I wrote about my new project: building my own DUM-E robot. And while I have a lot of idea’s for this project, I mainly spent my time waiting for the nessecery parts to arrive. So to ease the waiting, let’s work on making the passive side of the joint a little more sexy.

Robotic Arm:

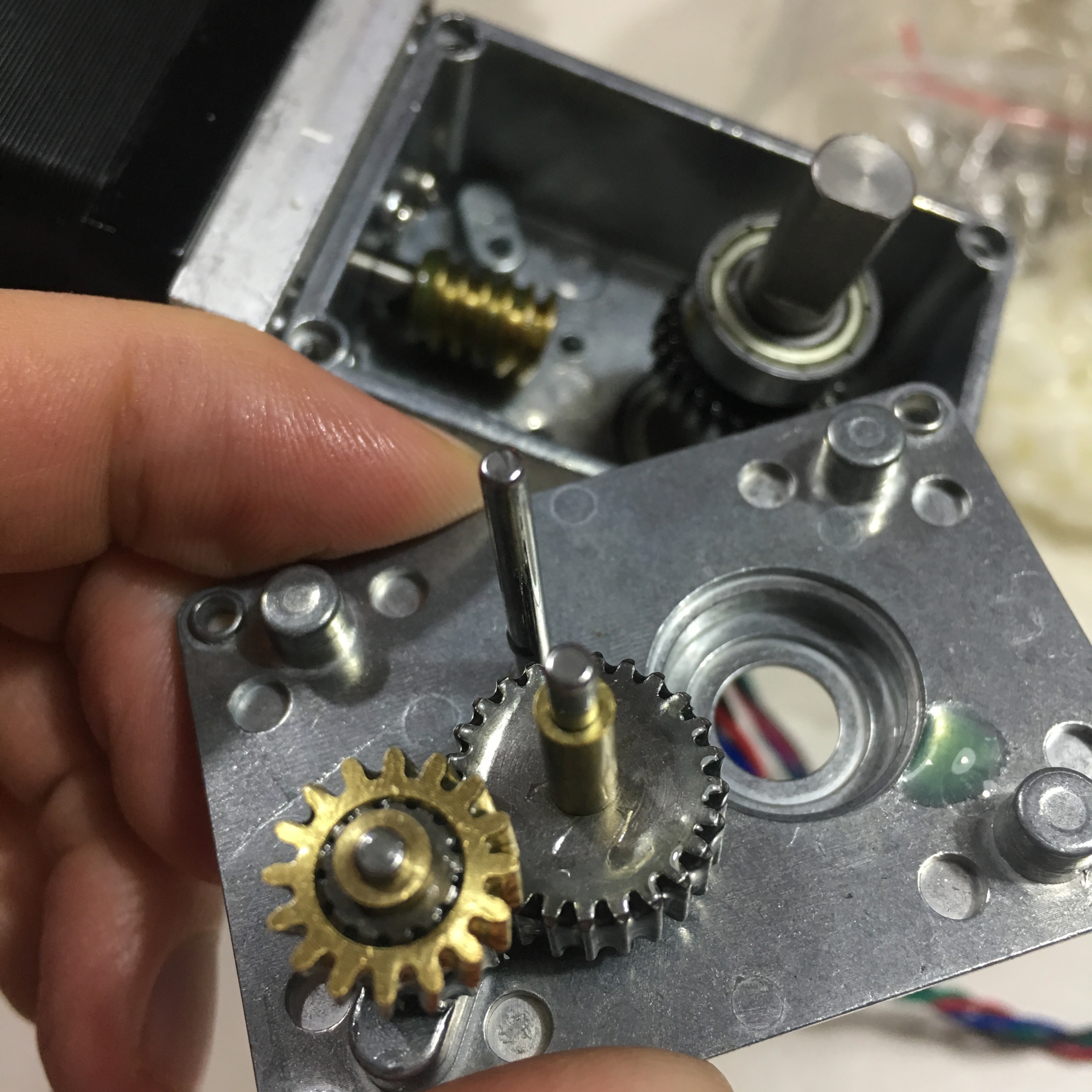

My first attempt of building a transmission box.

In the last few weeks I mostly focussed on the aesthetic of my Robot Arm project. Now that I finally received the necessary gears, It’s time to work on the transmission box.

Robotic Arm:

The Backlash of Cheating

A few weeks ago I finish the first prototype of the stepper transission I need for my Robot Arm joint. In the process of improving this transmission, I tried some 3D printed gears and ended up cheating …

Robotic Arm:

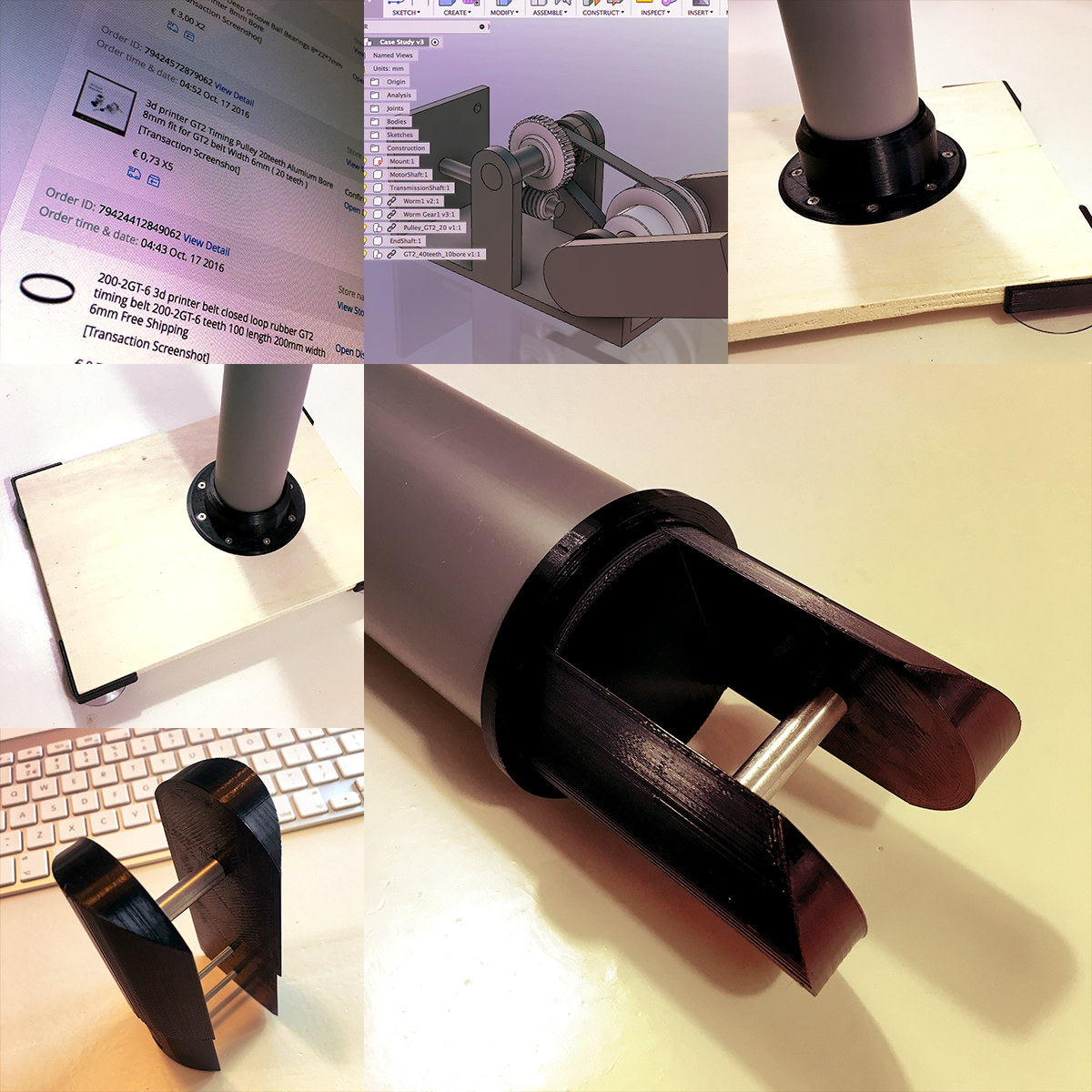

Pulley & Belt Transmission

Admittedly, building a robot arm joint transmission is way more difficult than I expected. But where’s the fun in a simple project? In my last post, I explained why a geared transmission doesn’t work. This week I’ll try a new approach.

Robotic Arm:

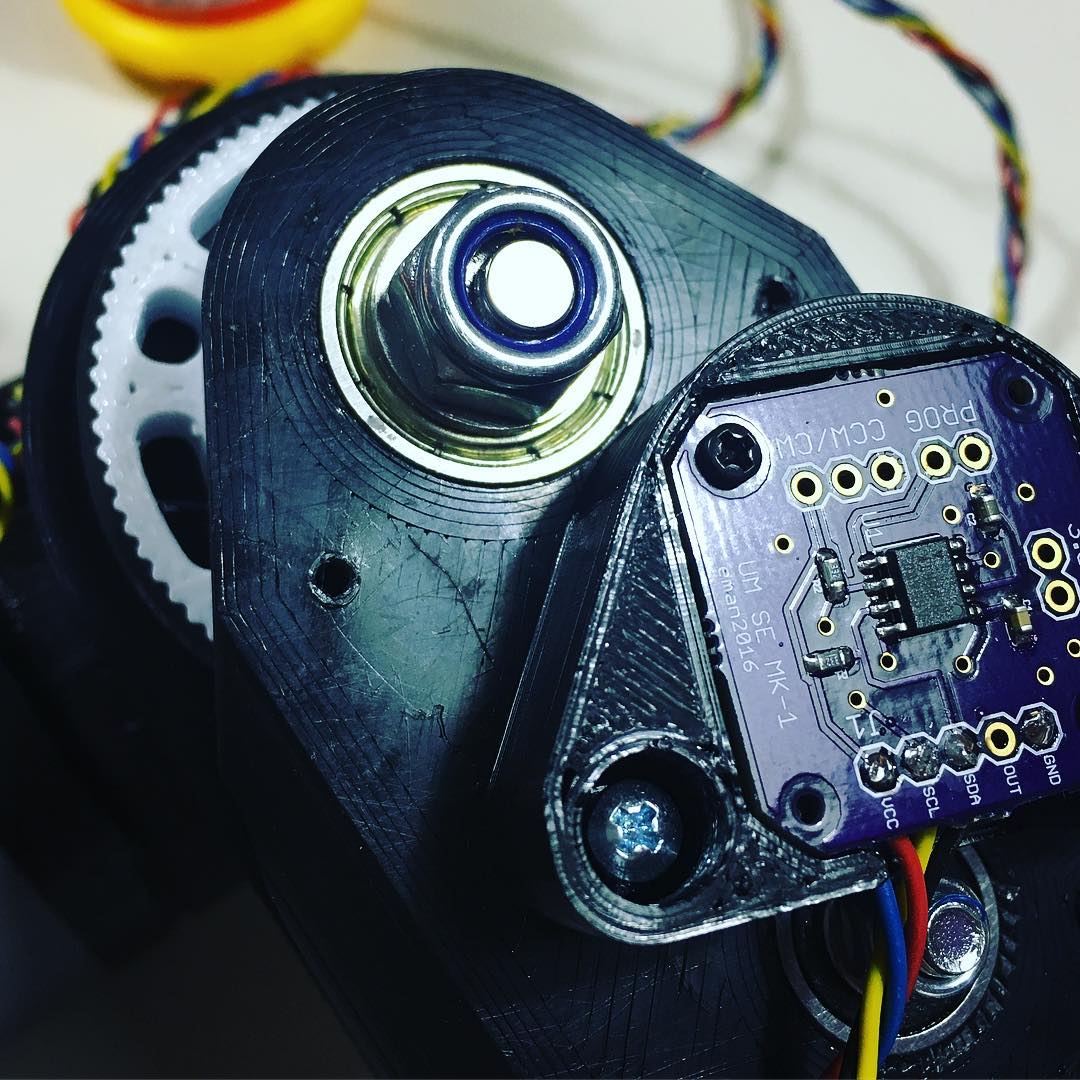

Give me some feedback!

To improve my robot arm’s accuracy, I wanted to add an absolute position feedback mechanism. Aside from it’s accuracy, it would also prevent the need for end stops. But most importantly, it would give me a reason to play with a AS5600 12-bit on-axis magnetic rotary position sensor.