A few weeks ago I finish the first prototype of the stepper transission I need for my Robot Arm joint. In the process of improving this transmission, I tried some 3D printed gears and ended up cheating …

Robotic Arm: My first attempt of building a transmission box.

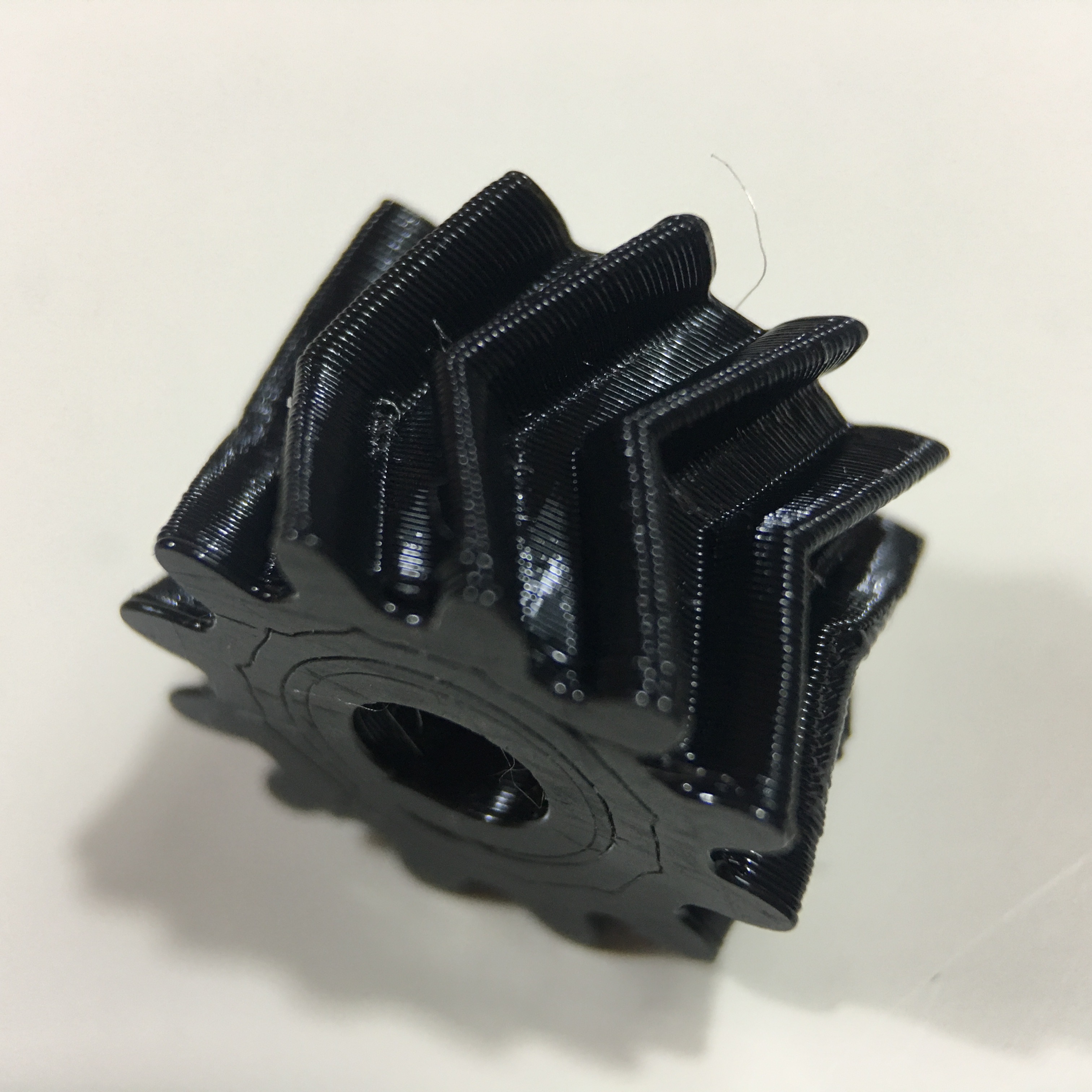

When you have a 3D printer, you simply can’t skip a little 3D printed gear test. With the help of the Fusion 360 Helical Gear Generator, I created a some small gears. Printing those was a bit of a challenge, but the enresult was this cute little gear …

But although it’s a fun little experiment, 3D printed gears don’t match the accuracy of metal gears. So once again, I opened the website of my “preferred supplier” and started looking for some cute little candidates.

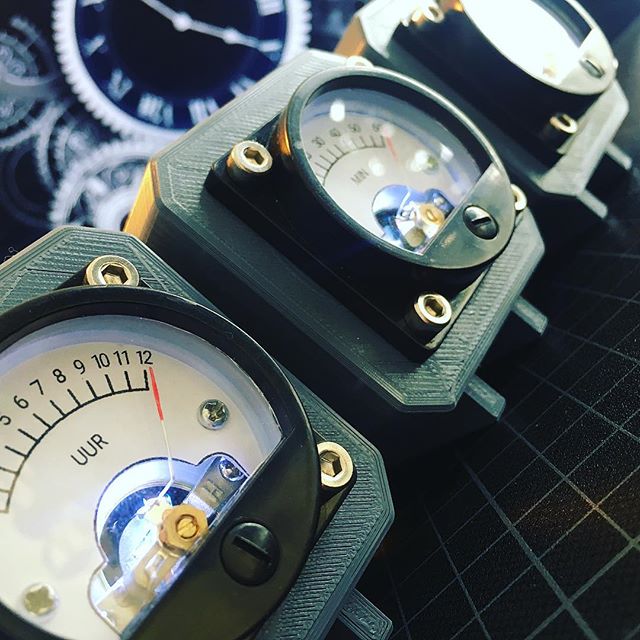

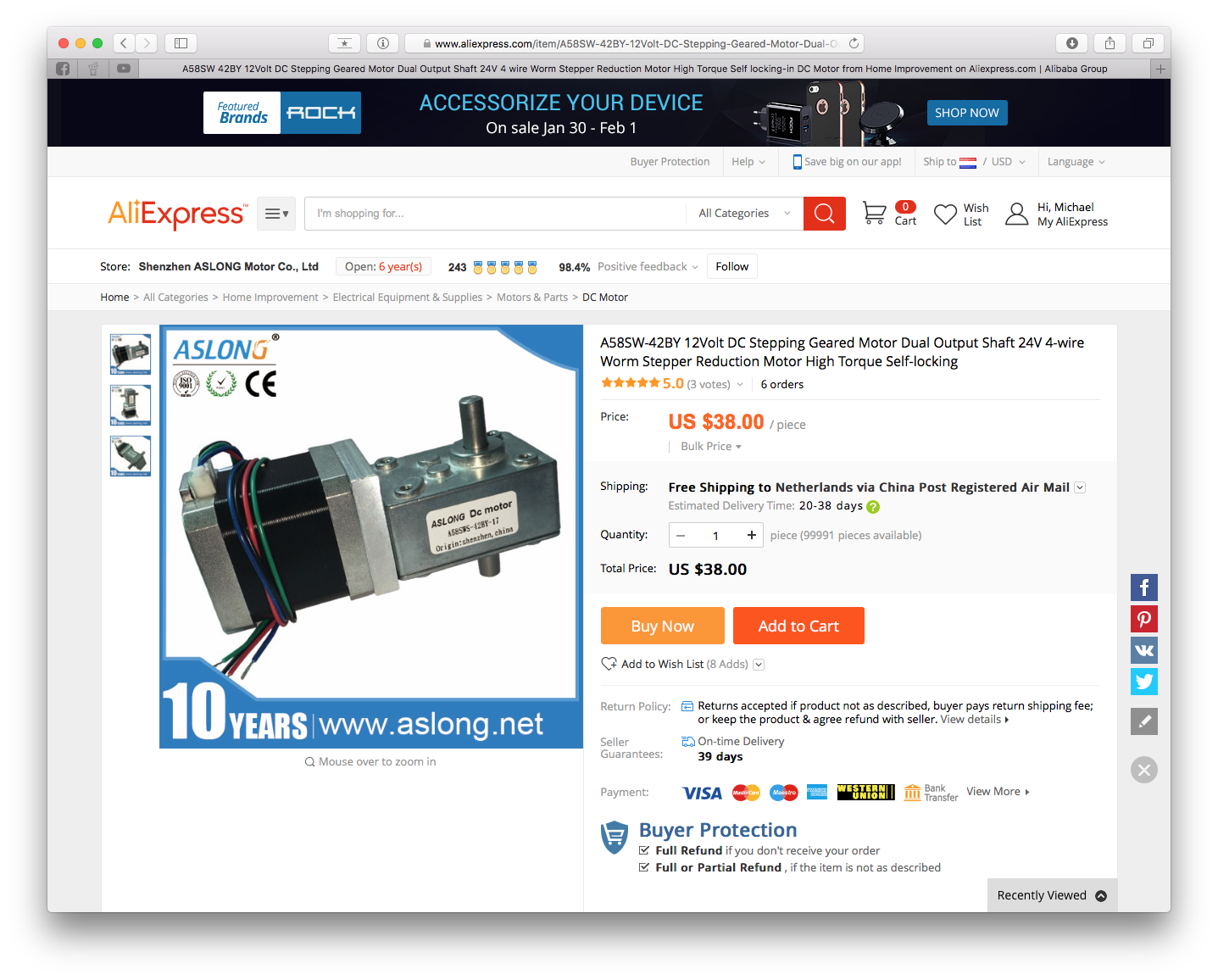

In this process, I ran into something very seductive. It feels a bit like cheating, but it was the perfect way to test the possibilities of the worm wheel approach.

Indeed, I found a 90 degrees geared stepper motor with a dual output shaft. Exactly the type of transmission I’m trying to built.

Luckily, the delivery of this motor didn’t take long. So, let’s continue the fun!

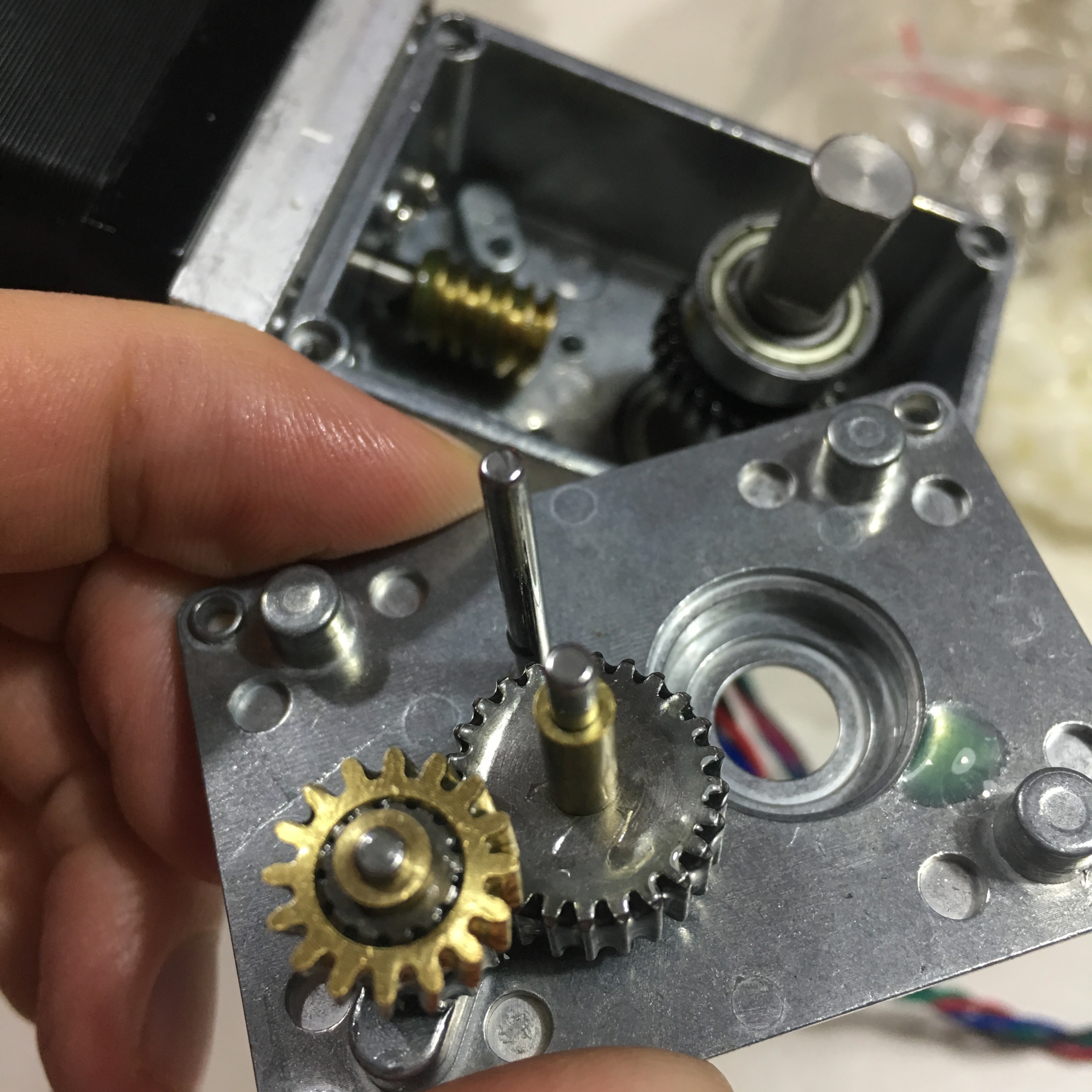

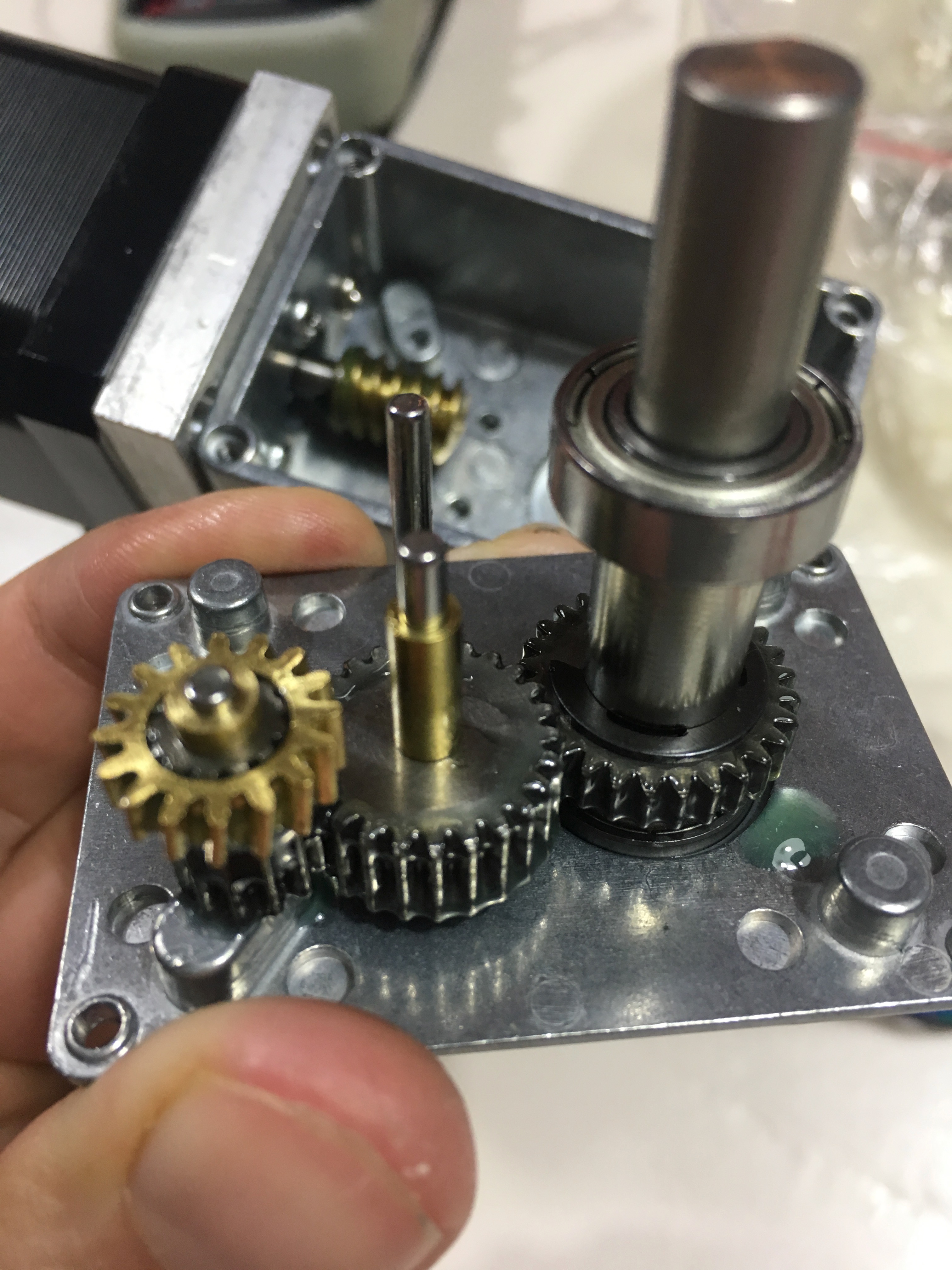

Of course, the first thing I did when it arrived, was opening the transmission box. Let’s take a look at the geared magic on the inside of this piece of mechanics. You can guess the fun part: closing it up again took me way longer than I expected.

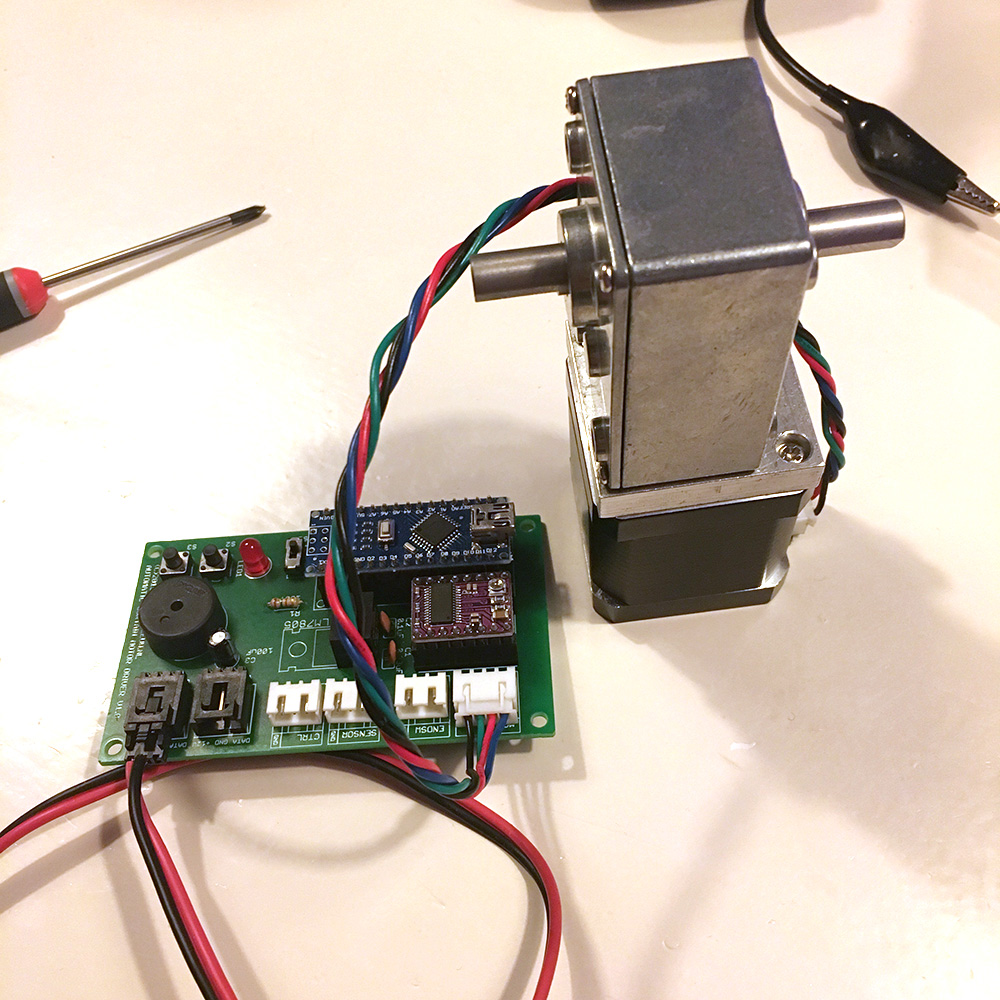

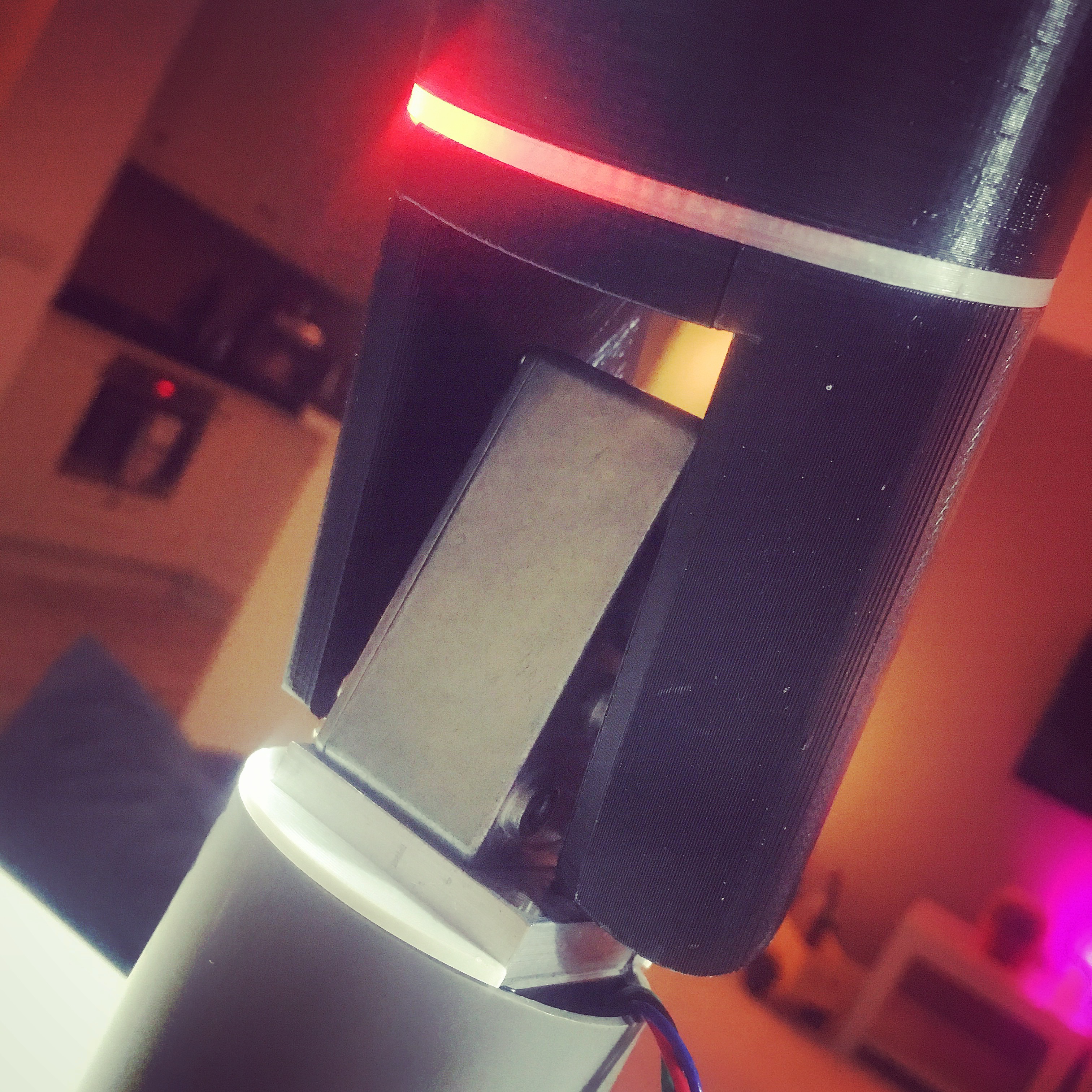

Once again I used one of my spare Automatic Curtain Controllers to give the stepper motor a test spin. It has the benefit of on board buttons, and a feedback led. With some modified firmware, testing the motor is as easy as controlling a regular DC motor.

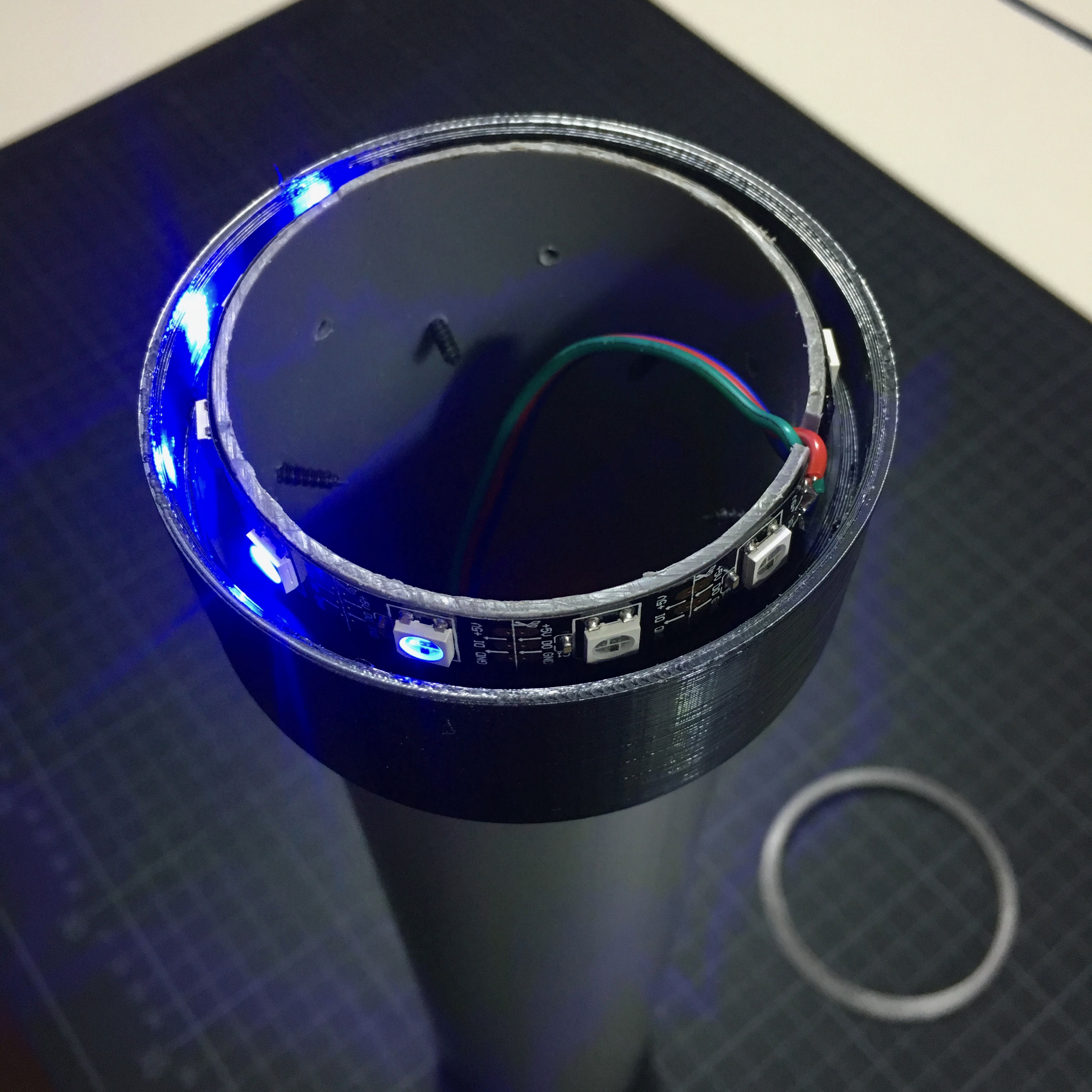

The metal box and the LED ring make up for a sexy macro shot. But if it works as good as it looks, is something we’re gonna find out next!

The first movement is exciting as hell, but if you look closely, you might be able to spot one big issue …

The transmission box really has a lot of backlash. Or to be a bit more precise: it suffers from a small bit of backlash, which translates into a lot of movement over the full length of the arm.

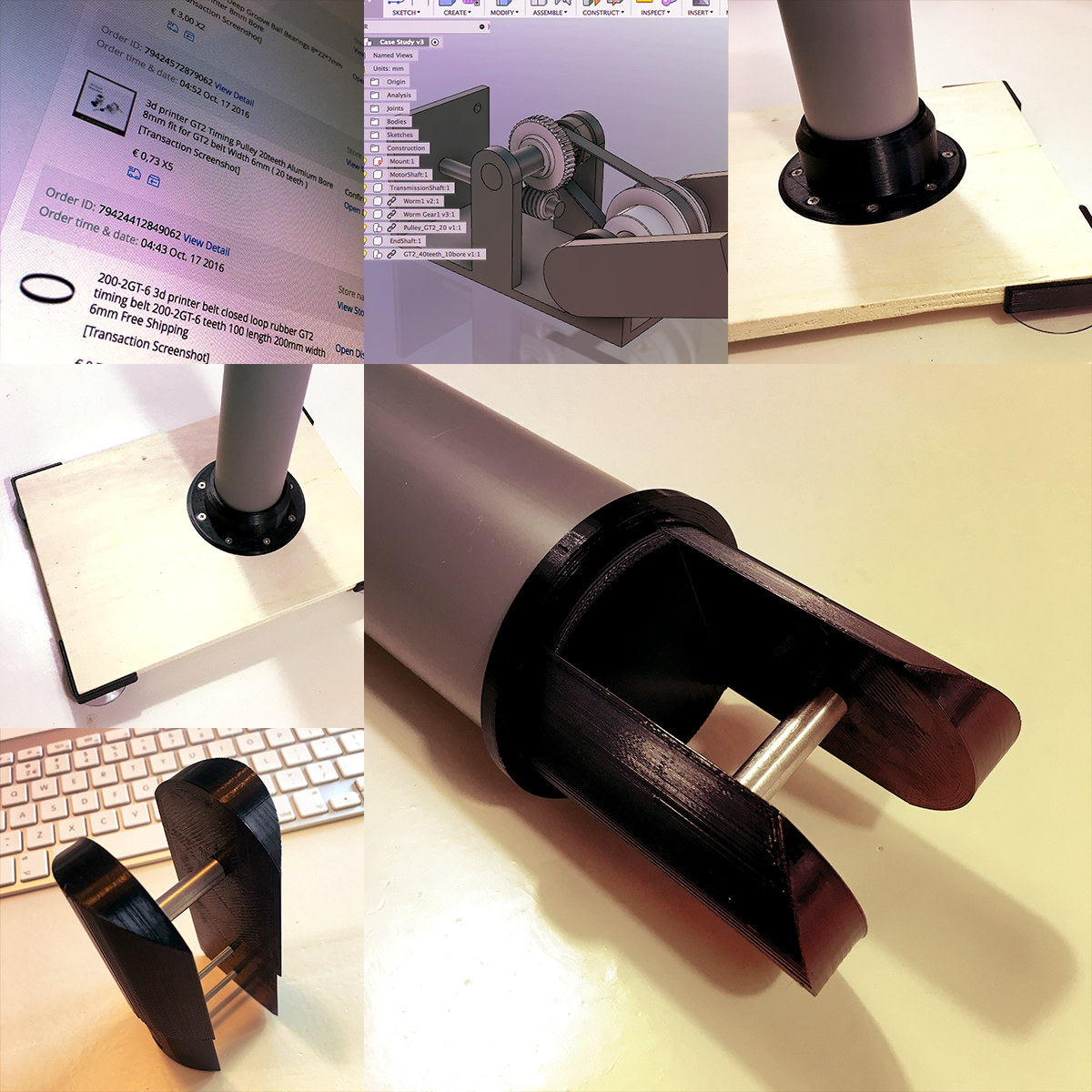

I did a lot of research to see if this is something I can solve when using regular (affordable) gears or gear boxes. But since I can’t afford a bunch of Harmonic Drive Motors, my only option is a transmission that uses pulleys and timing belts.

Back to the drawing board!

I hope to show a a fully functional transmission box soon!

Robotic Arm: Pulley & Belt Transmission