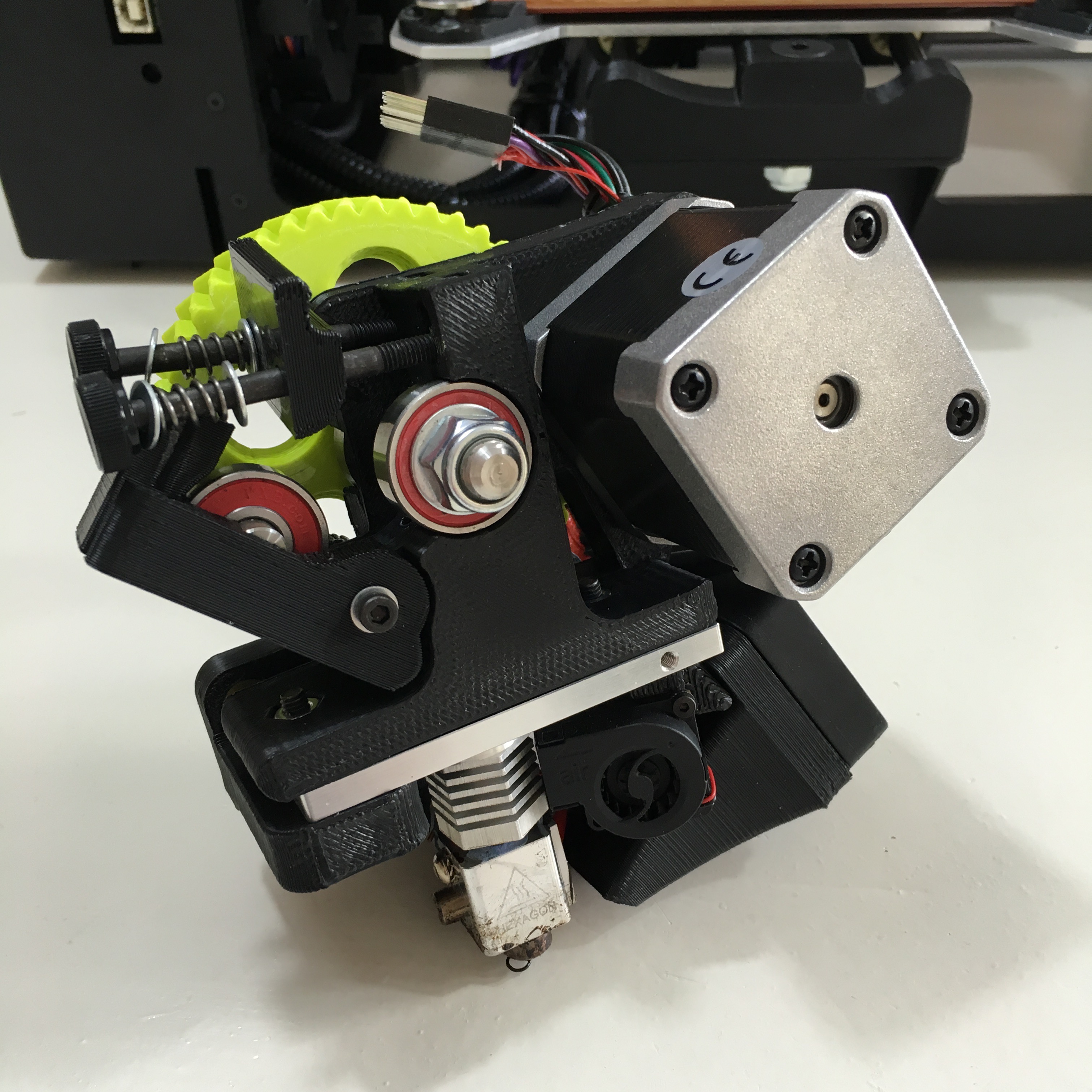

Lulzbot Repair

With over a year of 3D-printing and only a hand full of failed prints, I can honestly say my Lulzbot Mini 3D printer is a reliable piece of hardware. But after a recent failure, it turned out my printer needed some extra love.

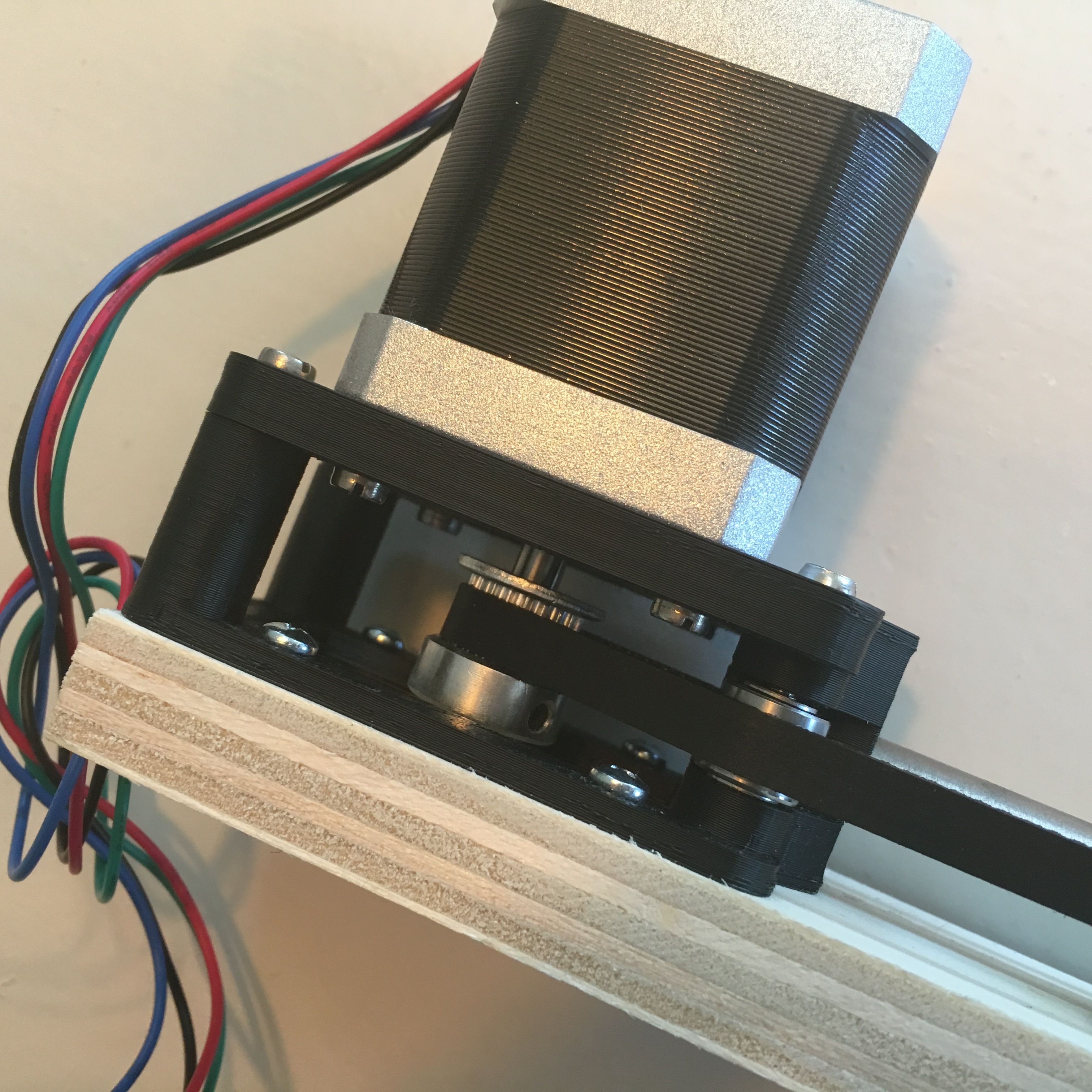

Automatic Curtains:

The most permanent temporary solution.

With the final Motor Unit moutend, and the cables routed to a central location, it is time to install a simple control unit. Unfortunately, the sophisticated button pad I created a while ago, wasn’t functioning as well as I hoped. So while I fix these issues, I need to mount a temporary control unit.

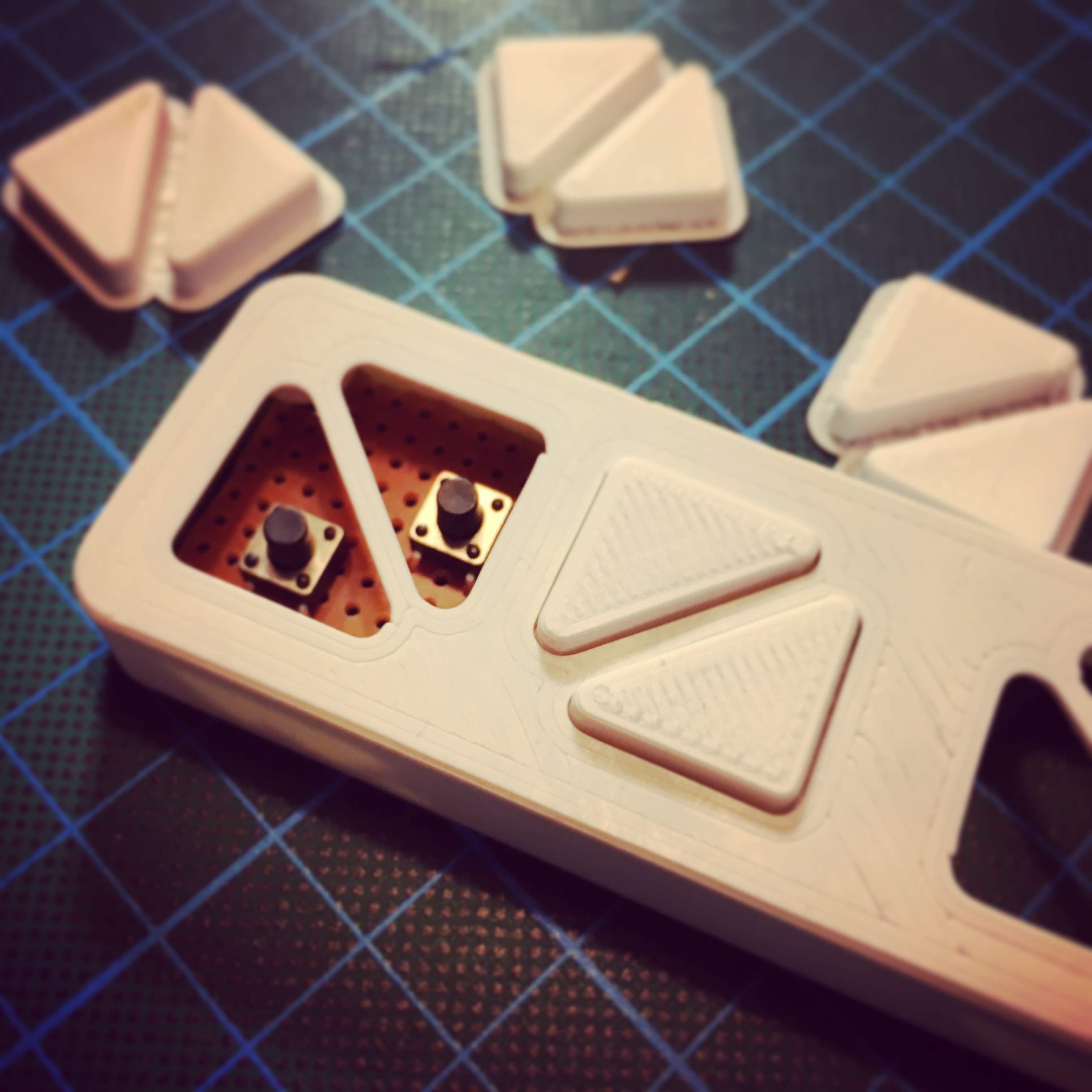

Automatic Curtains:

Push the button!

With most of the automatic curtain motor units done, it is time to start worrying about the controls. With projects like these, you always have to work on the WAF-score. The Wife Acceptance Factor. So a simple control pad is a must.

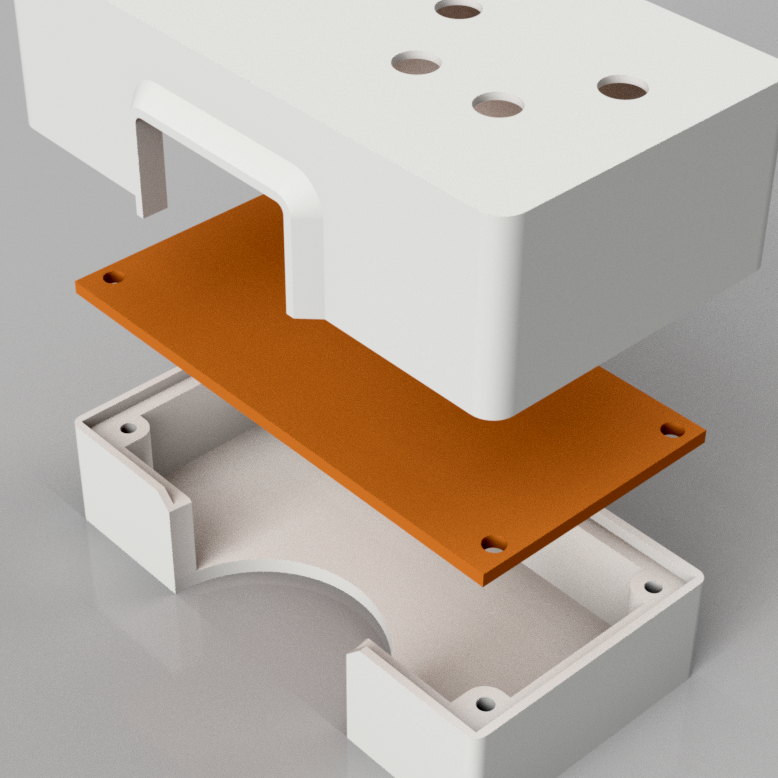

Automatic Curtains:

Assembling the motor units.

Now that the prototype is finally complete, it is time to start assembling the 4 final motor units: a combination of wood working, 3D printing and some minor cussing. Because I expect some small adjustments along the way, I’ll make the units piece by piece.

Big Daddy is watching you!

Don’t ask me how, but somehow I managed to convince my girlfriend that is was a good idea to buy a Nest Cam to keep an eye on my future-son’s bedroom. And if that’s not special enough: I even convinced her that it is a good idea to mount it inside the baby crib.

Expecting a baby? Start printing!

If you are a maker, you probably know the feeling: use everything as an excuse to invent something new. And while most people think I should focus on reading parenting books, I think my unborn child is the perfect reason to spend my time behind my 3D-printer!