Under my umbrella, ella, ella, eh, eh, eh!

So, it has been a month ago since my last blog post. Reason for this is the birth of my beautiful second baby boy, Luca! But after some quality family time, it’s now time to pick up the tinkering, and start making things! Of course we start easy, so this week I’d like to show you the beautiful power of 3D printing and how it helps me to be an awesome dad!

Pulley Power!

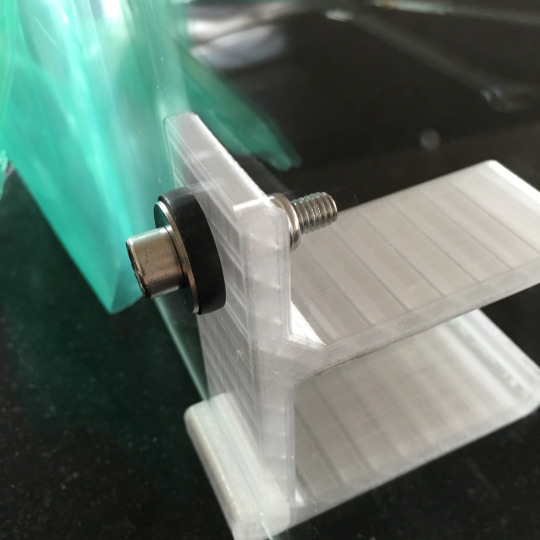

For both my automatic curtains as well as my robot arm joint I ended up using GT2 belts and pulleys. But although printing GT2 pulleys is possible, the 3d printed pulleys tend to skip some teeth quite easily when they are used in high torque applications. Just as an experiment I though to give HTD 5M belts a try.

Activity Board:

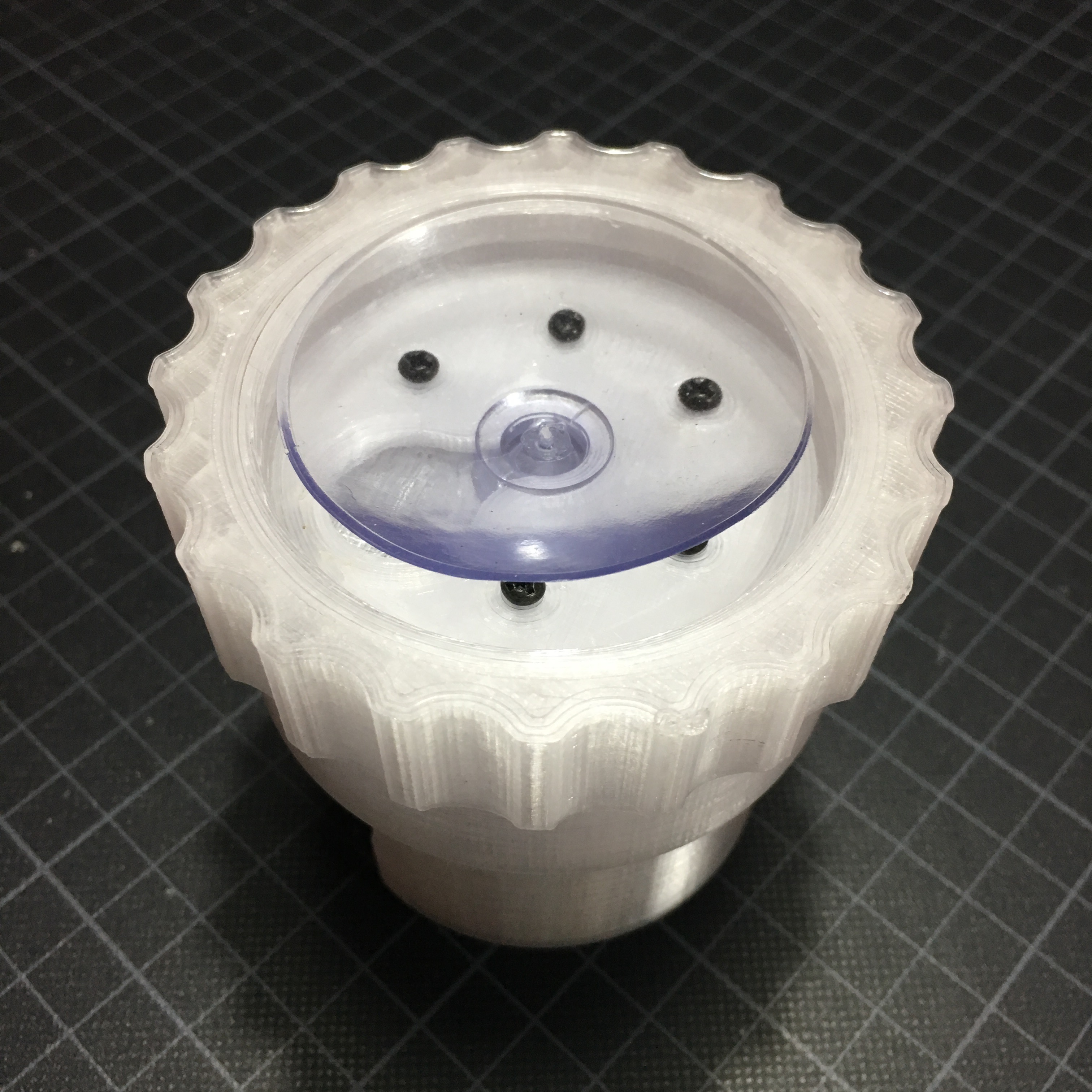

The dial on the board goes round and round

Creating an nice big dial knob for the activity board, isn’t that difficult since I own a 3D printer. But to make it a big more special than the average dial, I wanted to add a nice light effect to the button.

The Grinder Mount Adapter

Although I’m still working on my son’s activity board, I haven’t got much progression to show. So this week, I wanted to talk about a fun simple 3D printing solution I designed yesterday. As a real coffee addict, my coffee grinder is what it’s all about.

Fixing my Caliper

My caliper is one of my most beloved tools. If you’re into 3D-printing and 3D-design or any other type of engineering that requires accurate measurements, you know you can’t live without it. But unfortunately, mine is flawed. Time for some fixing.

Baby Spa

After last weeks shower repair I really got bitten by the bug of 3D-printed bathroom improvements. This weekend I spent some time creating a baby-spa for my mini maker boy who loves to take a bath in the shower base.

3D Stair-gate

One of the things I wasn’t expecting when my girlfriend was expecting our first child, was the amount of home improvement that was necessary protect our house from our small crawling wrecking ball. This week, it was time to protect our staircase.

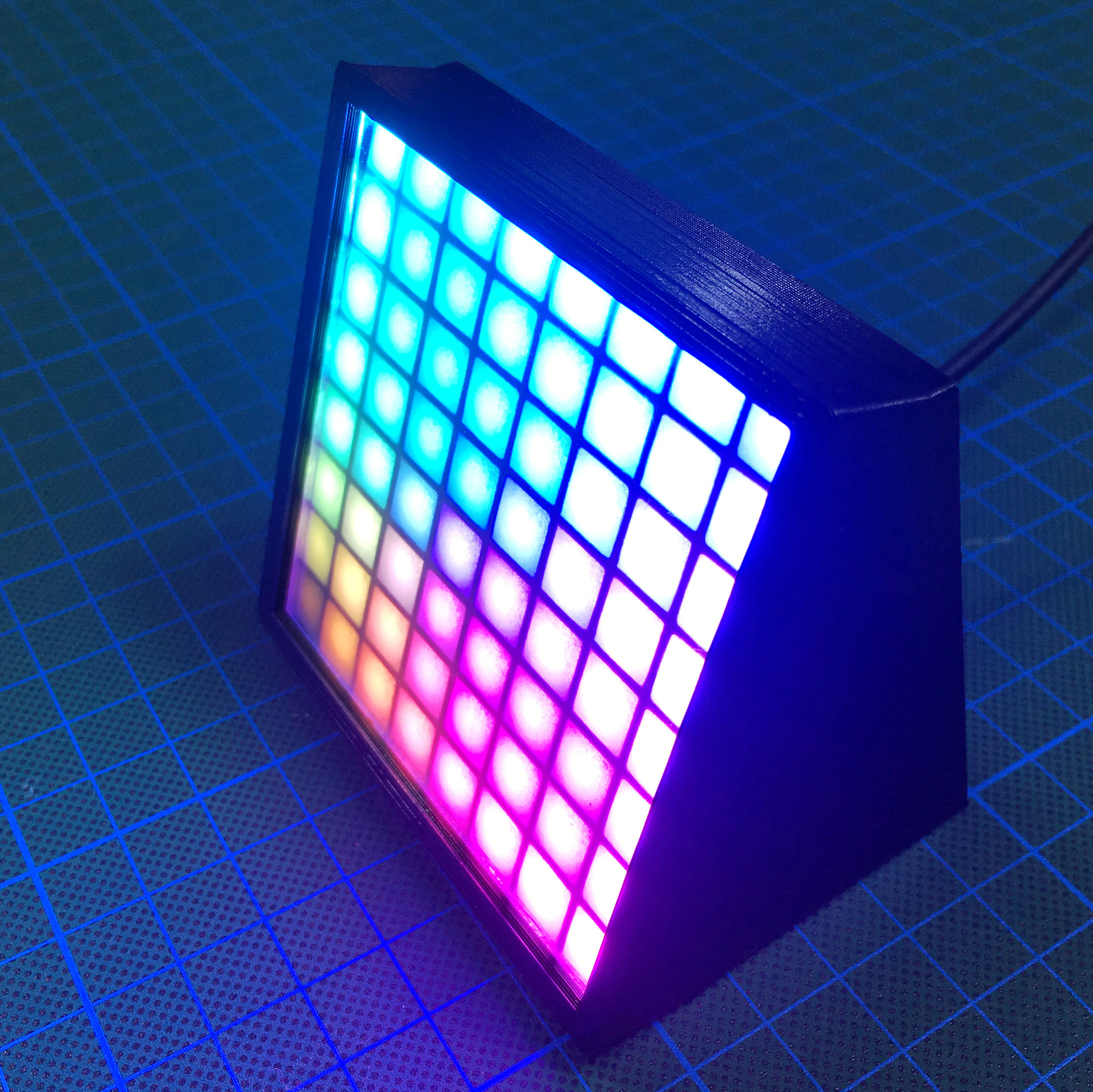

The NeoDisplay

As most of the Arduino tinkering makers, I have some NeoPixels LEDs in my drawers. Especially the 8x8 NeoMatrix is a beautiful piece of illumination. But till now, I didn’t have any good use for it yet. Time to make it a bit more useful!

3D-parenting

It’s June! Which means two things: it’s getting hotter each day. And my son is 9 months old. Together these facts are a good reason for a nice 3D printing project.

Pimping my ride!

While I’m still waiting for some Chinese parts to arrive in order to finish my Wifi controlled curtains, I took some time to pick up a totally different project …

Automatic Curtains:

Preparing for Development

With the fully operating hardware, it is finally time to start working on the real firmware for my automatic curtain motor controllers. The current firmware is quickly thrown together and contains a few annoying bugs which need to be solved. To make the development process a bit easier, I made a small development unit, allowing me to test and debug my software without the need of closing and opening my real curtains.