A Place To Sleep

It’s been 10 months since my second son was born. And Since then, he has been sleeping in a crib in our master bed room. And as much as I love him, It was time for him to move out. Out of our bed room at least … Time to built him a place to sleep.

MusiCubes:

The Finishing Touch

Starting a project isn’t difficult. Finishing is. Or as they say: the last 20% is always the hardest part. But no worries, today we’ll finish this project by working on the final details.

MusiCubes:

Concept & Prototyping

Most of my projects start behind my desk, Tinkering. But every now and then, new ideas come to mind while I’m not geeking. Just as with my MagicMirror, those projects and ideas are usually the best. Today I start a new project which, just as with my MagicMirror, popped in my mind far away from my soldering iron and computer: A digital music controller in an analog form factor.

What are you looking at?

2 weeks ago I strained my back while doing the heavy duty task of putting my 7 month old son to bed. As a lot of us desk nerds, my core muscles are non existent, so this was a matter of time for it to happen. Unfortunately it means I currently can’t spent any time behind my desk. Luckily there are other ways of fulfilling my maker needs.

Activity Board:

Assembling the panel

After a succesful intergration of the push buttons it is time to wrap up the front panel. With 9 switches, 3 buttons, 2 displays, 1 slide pot, 1 rotary encoder and a lot of LEDs, this includes a lot of wiring.

Activity Board:

Spray Away!

After I finished the front panel, and getting an approval of Enzo, the next step in the process of the activity board is finishing the casing. A nice reason for some evenings in the shed.

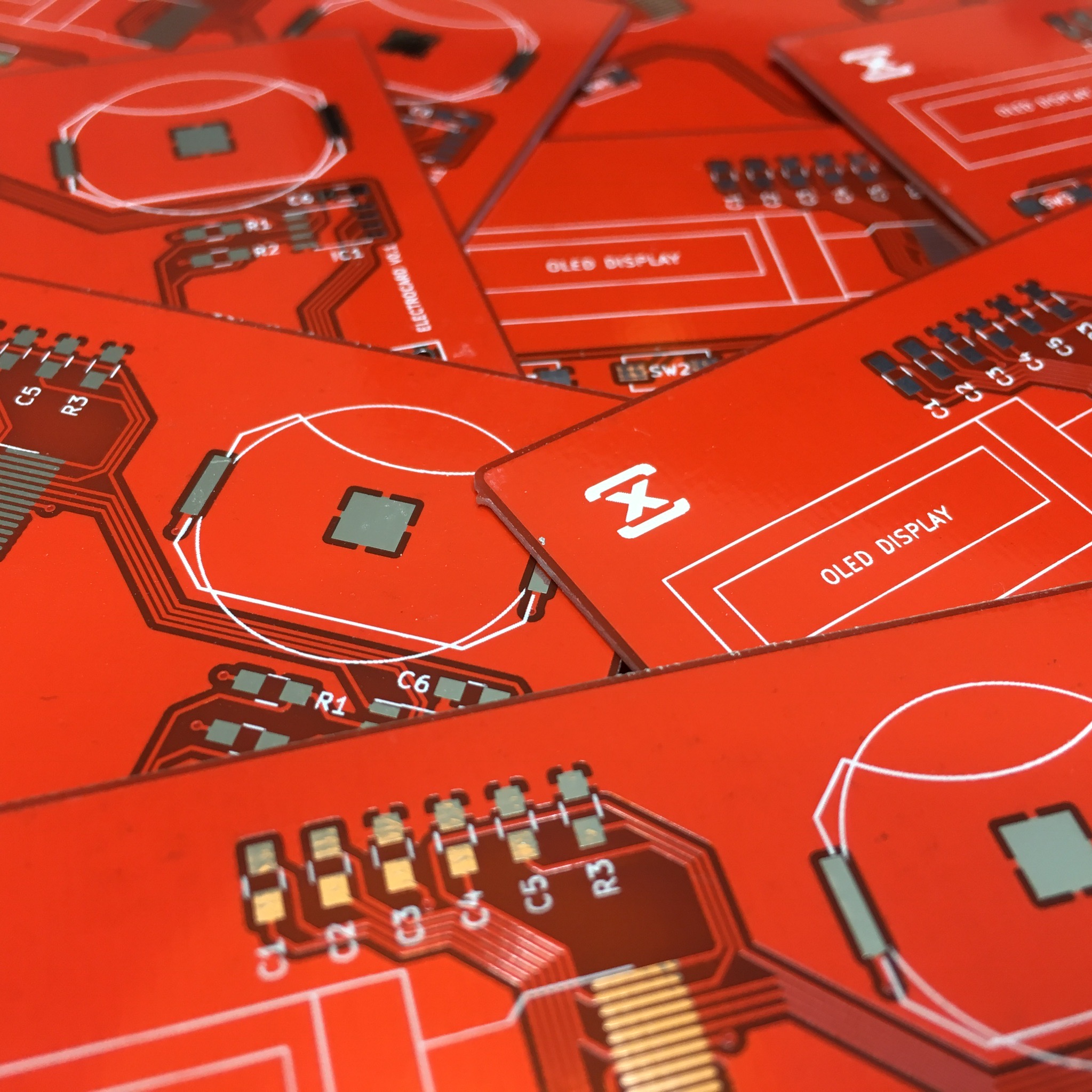

Electrocard:

The Design

Ever since I have my own company I wanted to have a PCB business card. Of course I wouldn’t be the first, but it would definitely give a nice touch to my company’s identity. And since I wanted to give KiCad a good try anyway, why not go for it?

Activity Board:

Building the Box

Before I can work on the front panel design of Enzo’s Activity Board, I need to know the exact dimensions. This can be figured out either by using some math, or by simply just measuring it. I choose the latter, but this means I first need to build the box that holds everything in place …

Activity Board:

Adjusting the Switches

Two weeks ago, I wrote about the Activity Board I’m building for my son. Since I want this panel to use a 5 volt power supply, i needed to tweak some of the buttons I’ll be using.

Activity Board:

Enzo's Control Room

With all of my projects that include one or more buttons, I know one thing for sure. The buttons will be extensively tested by my 1,5 year old tinkerer Enzo. My Automatic curtains need to open and closed more than a few times a day, and my robot arm’s test buttons are being pressed repeatedly even while it isn’t powered on. I think the message is clear: he wants his own buttons!

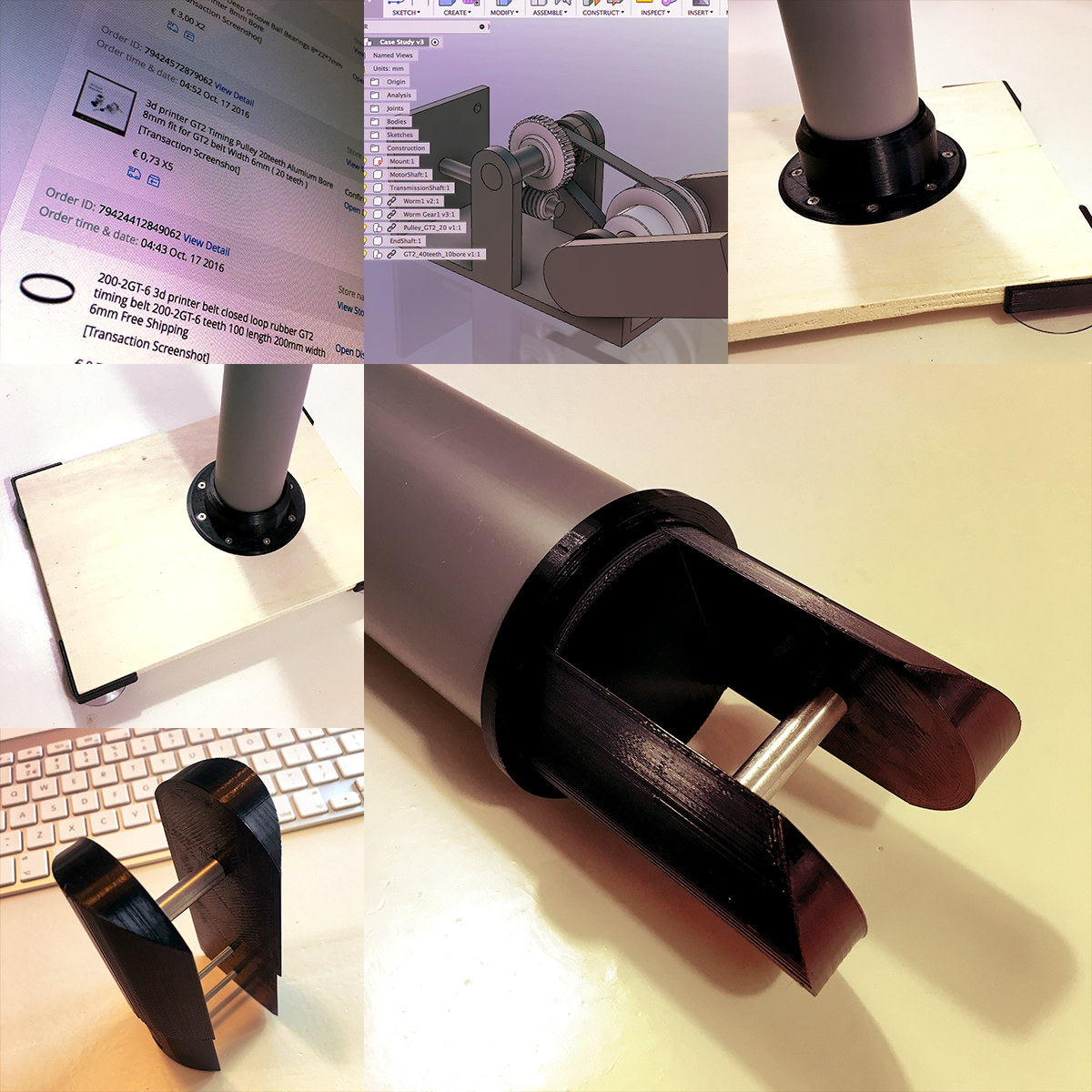

Robotic Arm:

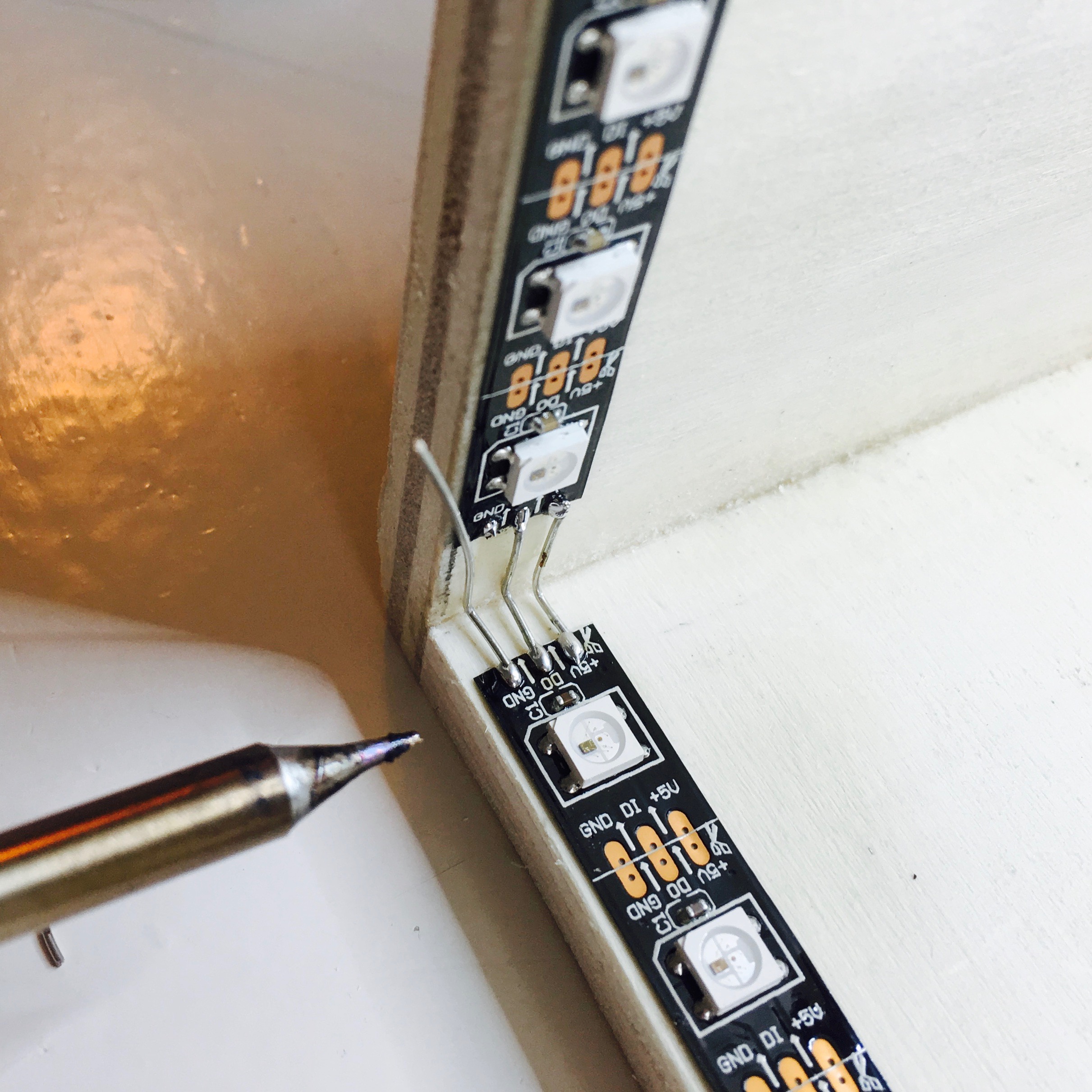

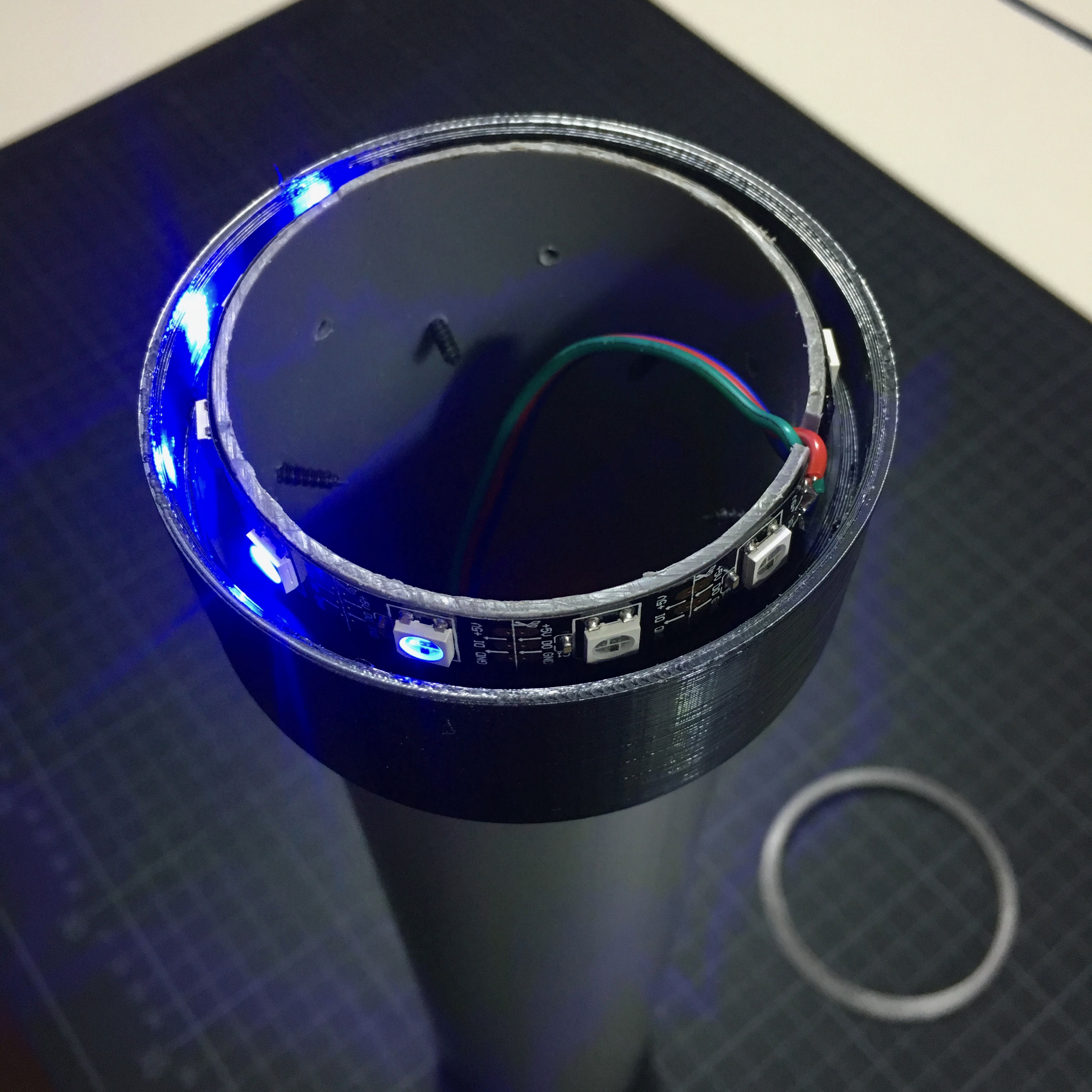

Illuminating the joint.

2 weeks ago I wrote about my new project: building my own DUM-E robot. And while I have a lot of idea’s for this project, I mainly spent my time waiting for the nessecery parts to arrive. So to ease the waiting, let’s work on making the passive side of the joint a little more sexy.

Robotic Arm:

Building my own DUM-E Robot!

Let’s face it. Every maker wants to become the next Tony Stark. And even though my Power Suit looked fun, it wasn’t really capable of protecting the world against the bad guys. Let’s work on something a bit more doable …

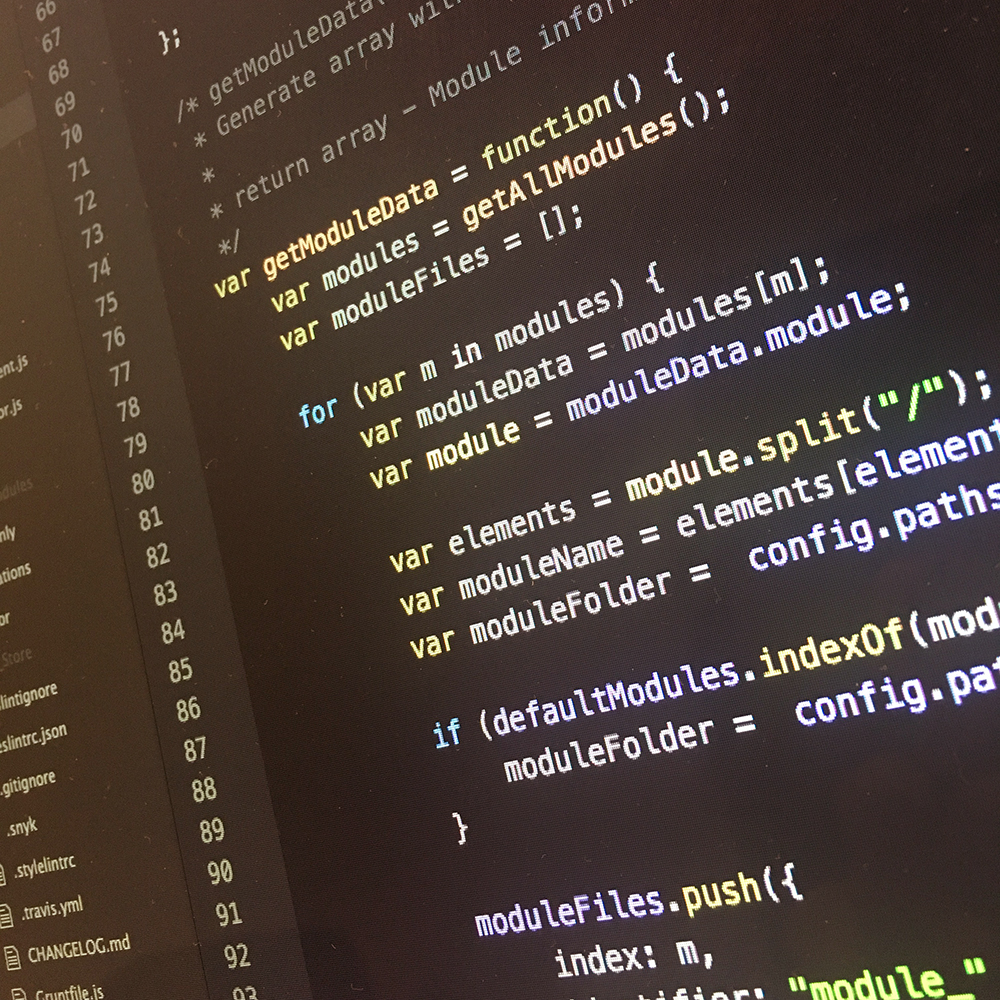

Behind my computer ...

Most of my blogs are about my physical projects, my tools like my 3d printer, my Rigol power supply and scope and my beloved soldering iron. But, truth to be told, most of my time is spent behind my computer. Today I’m going to give you a rundown of tools and ingredients I use the most when working on my Mac.

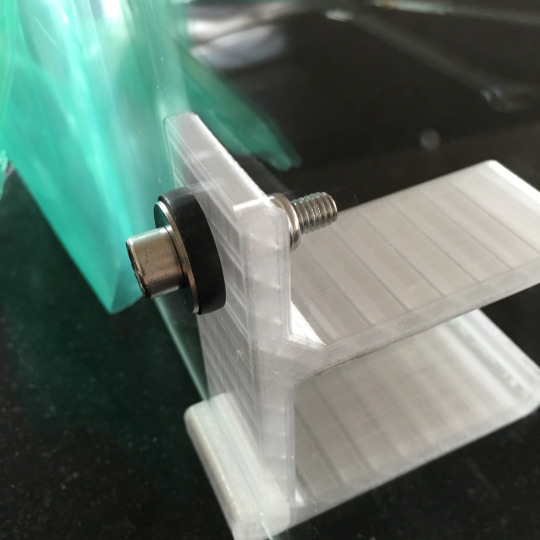

3D-parenting

It’s June! Which means two things: it’s getting hotter each day. And my son is 9 months old. Together these facts are a good reason for a nice 3D printing project.

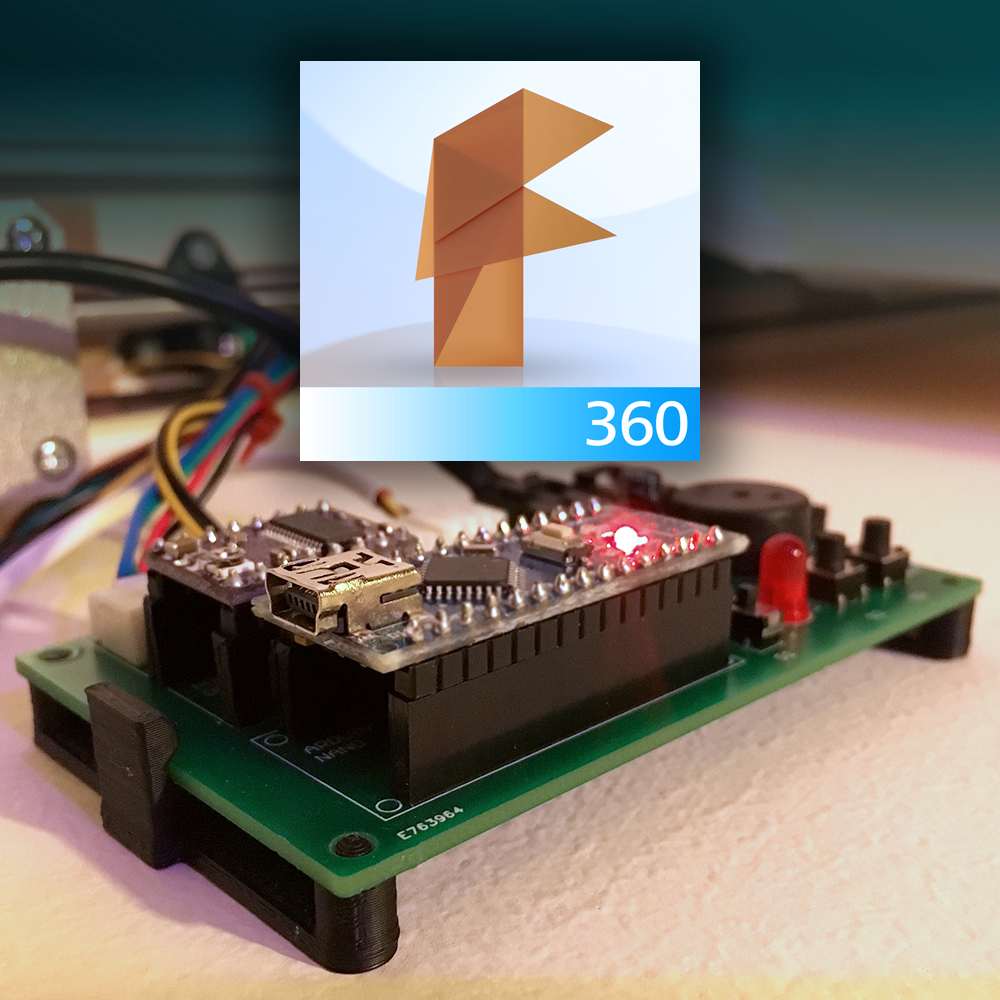

Automatic Curtains:

Designing a PCB Mount in Fusion 360 [Video]

With the Automatic Curtain Motor Controller ready, it’s time to mount it below the motor unit. Since I want it to be easily removable for maintenance, I used Autodesk Fusion 360 to quickly draw a 3D printable PCB mount.

The Next Big Thing

Last week I finished my Power Suit project. Although some quality couch time would be nice, I’m always working on new projects. Since I’m not sure what the next project will be, I’ll be sharing some of the ideas I currently have.